Feedrail FR100 Series Trolley Service

Busway and Crane & Hoist Electrification System for Movable Trolley Service

General Information:Feedrail® systems are capable of providing multi-purpose trolleys or stationary plug-ins for installations requiring a source of electrical power which can be reconfigured without rewiring. These systems provide moveable outlets for electrical power along their entire length. The systems are especially suited for use where conventional wire systems would be cumbersome and costly. Plug-in Jacks with stationary power take-offs, are available for all Feedrail® systems. The busway-supported outlets called “trolleys” (Feedrail® 60 system only) make contact with the enclosed bus bars and provide a continuous moveable connection for electrical devices. The trolleys are easily inserted and removed through door-busway sections. As additional outlets are needed, trolleys (Feedrail® 60 System only) or stationary plug-ins can be quickly and efficiently inserted, their numbers being limited only by the current-carrying capacity of the busway and the capacity of each outlet. Reliable design assures uniform contact pressure, limiting work stoppages due to electrical and mechanical interruptions in supplying power. Advantages of these systems include low installation costs with complete re-usability; ease of adding outlets as required; electrical and personnel safety; compactness; dependability and minimum maintenance expense. All “busway (track) sections” are factory assembled for ease in handling and rapid installation. No special tools are required. Systems are designed for indoor use in non-hazardous, non-corrosive, dry atmosphere. |

Basic Information:

More Information:

|

UL & CSA Listed

Feedrail® is listed by Underwriter’s Laboratories, Inc. (U.L.) under BUSWAYS AND ASSOCIATED FITTINGS (File E11348 for Feedrail® / File E165922 for Electro-Rail® ) and as a CRANE AND HOIST ELECTRIFICATION SYSTEM (File E31188 for Feedrail® ). Feedrail® is also listed by the Canadian Standards Association (C.S.A.) under WIREWAYS AND BUSWAYS (File LL-7907 for Feedrail® / File LL 103287-1 for Electro-Rail® ).

FR100 Trolley Series (Feedrail® “100”) — What It Is and What It Does

Feedrail® “100” is the modern flexible “Trolley Busway System” and “Crane and Hoist Electrification System” for distributing electric power. Basically, it is an electrified track in which the current carrying components are enclosed in a protective steel housing. Smooth riding internally track-supported trolleys take off current and provide power outlets anywhere along the length of the run.

Superior to ordinary wiring methods in safety, convenience and adaptability, it provides a dependable power source for both stationary and moving equipment. Its uses in industry are myriad — from powering hoists and cranes to providing current for portable electric tools, from the electrification of moving test lines to the control of large machine tools and to supplying the current for electrically driven hangar doors.

The Feedrail® “100” system is made up of standardized units, factory assembled for easy, fool-proof installation in the field. Its basic units include:

The Feedrail® “100” system is made up of standardized units, factory assembled for easy, fool-proof installation in the field. Its basic units include:

Track sections — straight, curved, door, expansions, sectionalizing and transfer sections — enclosing current carrying bus bars.

Accessories — coupling plates for joining track sections; feed boxes for connection of bus bars to the electric power supply; dead end caps for closing the end of track runs.

Trolleys — available in several types to meet a wide range of requirements including fusible and non-fusible types, with and without receptacles — internally track supported to provide current takeoff wherever desired.

Track sections can be supplied to form runs of any required length or contour. Hence it is “tailored-to-fit” the electric power requirements of industry, whether for modernizing an existing plant or for installation in a plant under construction.

Feedrail® “100” operates with equal safety of any required level from ceiling to floor. While the majority of installations are overhead, numerous low-level installations have been made, including some along the base of production lines. All installations have proven entirely satisfactory in operation.

Designed primarily for indoor service in essentially dry locations.

Design & Construction 2 & 3 Pole Systems

Busway and Crane & Hoist Electrification System For Movable Trolley Service

Current Carrying Capacity

Current Carrying Capacity

Track rating 100 Amperes (continuous); 150 Amperes (intermittent) Trolleys rated 20, 30, 40, 60 and 100 Amperes (continuous).

Voltage

600 Volts A.C. — 250 Volts D.C.

Track Supports

Malleable iron clevis type for tie rod. Fits all track accessories.

Track

Track

Track sections consist of a 13-gauge zinc-coated steel housing and the enclosed current carrying bus bars and insulators, all factory assembled in convenient lengths ready for easy, fool-proof installation on the job. The lower horizontal portions of the housing serve as smooth, rigid runways for the trolleys.

“100” Track sections are available in various types — Plain, Door, Sectionalizing, Transfer, Curved and Expansion Track Sections.

Bus bars are of hard drawn copper. They are amply proportioned to carry the specified current of 100 amperes per pole continuously, 150 amperes per pole intermittently, without overheating. Insulators are made of a high insulating and arc-resistant material. They are held in place on 9” centers by the casing.

Trolleys

Feedrail® trolleys are designed to provide stable clean power; arcing and hot spots are essentially eliminated. Stable clean power is required for trouble free operation of today’s computer controlled equipment and machinery.

Trolleys are available in fusible and non-fusible types.

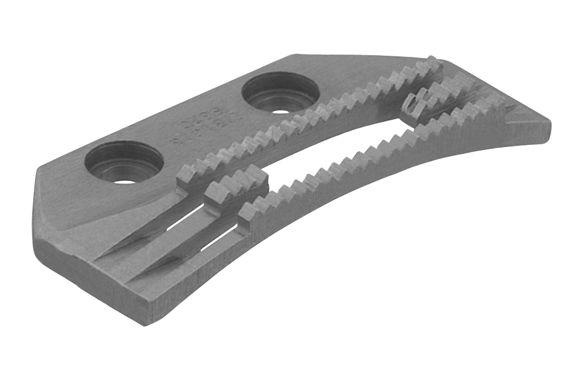

Basically, all Feedrail® “100” trolleys have a chassis-insulator-contact assembly. The chassis is heavy gauge steel. The trolley wheels and guide wheels are of the ball bearing type. A substantially proportioned insulator block combines the best insulating properties with high arc-resistance.

The trolleys for the “100” track system are furnished with various types of contacts. Bronze ROLLER contacts rated 20 Amperes, Copper Graphite BRUSH contacts rated 30 Amperes and Silver Tungsten Brush contacts rated 30 and 100 Amperes.

All Feedrail® trolleys have a polarizing tab on the chassis, which, operating in conjunction with a stop within the door track, permits insertion of the trolley one way only, thereby maintaining the trolley polarity as first wired. Provision for equipment grounding is included on all trolleys.

Feedrail® “100” system Roller Contact Trolleys generally are for intermittent movement applications where speeds do not exceed 200 feet per minute. Feedrail® “100” system Brush Contact Trolleys are for more frequent moving application such as on cranes and monorails where speeds do not exceed 350 feet per minute. Where continuous movement is required at these speeds, or where low voltage (under 50 volts) or low current (under 1 Amp.) is required, consult technical service group for recommendations. Weights in excess of 40 pounds per trolley are not recommended.

Cranes and Hoists

|

Because it eliminates the dangers and susceptibility to damage inherent in open wiring, and lowers maintenance costs, Feedrail® “100” is widely used for powering electric cranes and hoists. As these photos show it is readily adaptable to all kinds of installations, including those with curves, switches and transfers. |

|

Installing “100” Track

Feedrail® “100” track, trolleys and accessories are designed for ready installation without field alteration. Any qualified electrician can do the job. No special tools are required.

Feedrail® “100” track, trolleys and accessories are designed for ready installation without field alteration. Any qualified electrician can do the job. No special tools are required.

Installation should begin at a transfer or switch point or at an expansion track section if these are included in a track run. Otherwise, start at the feed box (center feed or end feed) and proceed away from that point.

The following four steps should be performed in the order given:

- Install hanger rods or other supports to which Feedrail® “100” is to be attached.

- Assemble Feedrail® components. The illustrations on the following pages show the step by step procedure. In many cases the assembling of Feedrail® “100” can be facilitated by coupling two or more sections prior to rising into position.

- Attach Feedrail® to supports, making sure adjoining track sections are on the same level and in correct alignment before the track connecting bars and bus bars are secured.

- Connect electrical supply cables to terminals of feed box.

NOTE: Where Feedrail® equipment has been ordered to the job site in advance of actual installation, the equipment should be carefully stored indoors in a clean, dry area.

Feedrail® “100” is designed primarily for indoor service in essentially dry locations.

Installing Transfer Track

Transfer Track sections are similar to Plain Track sections except that one or both ends are flared and have a tapered insulator serving as a guide for entrance of the trolleys.

Transfer Track sections are similar to Plain Track sections except that one or both ends are flared and have a tapered insulator serving as a guide for entrance of the trolleys.

On installations having transfer points, (turntables, slide or tongue switches, hangar door tail-gates, etc.) the Transfer Track sections should be installed first so that proper gaps can be set. These gaps between Transfer Track sections should not exceed ¼ inch.

(Transfer Track sections for use on turntables and slide switches, are not stock items but are manufactured specifically to conform to given dimensions.)

Where motor propelled hoists are used on runs which include transfer points, it is necessary to use two electrically interconnected trolleys. The two trolleys must be spaced sufficiently so that current is maintained to one trolley while the other crosses the transfer point. Duplex Transfer Type Trolleys have been designed particularly for this application.

Transfer Track sections at transfer points must be aligned accurately, both horizontally and vertically. They must be supported at the transfer ends by an FR-124 Transfer Point Hanger Set. (Hook bottoms of Transfer Point Hanger Set into slots in the under edges of the track housing. Bring the plates together and fasten to support with bolts as shown).

In every case the mounting of Transfer Track sections should be designed to insure a rigid installation. They should be sway braced to maintain alignment.

Sections are installed and coupled to adjoining track sections as shown in Joining Sections With Coupling Plate Set FR-102.

Building Expansion Track

At least one Expansion Track section should be installed in each 400 ft. of track run to compensate for the cumulative differences in expansion and contraction between the steel casings and copper bus bars. Additional Expansion Track sections may be required if the installation is subjected to a wide range of temperature changes.

Expansion Track sections must be used wherever an installation is made across a building or structural expansion joint.

The standard 10' Expansion Track section is designed to provide 2” of expansion and 2” of contraction above and below the normal 10' length, at 75°F. At the time of installation, the length of the Expansion Track section must be set in accordance with the table below.

When used at points other than a building or structural expansion joint to compensate for unequal expansion or contraction between the steel track housing and copper bus bars, support the Expansion Track section by the coupling plates at each end and by the center support plates from suitable support brackets.

When used across a building expansion joint, center the Expansion Track section across the building expansion joint and support at each end from coupling plates and from the center support plates. Center support must be on the same side of the building expansion joint as the side of the expansion section stenciled “STATIONARY.”

Length Settings for Standard 10' Expansion Track |

|||

|

Installation Temperature |

Distance in Feet * |

||

|

100 |

200 |

400 |

|

|

100°F |

9'11-3/16” |

9'11-5/8” |

9'11-¼” |

|

75°F |

10' |

10' |

10' |

|

50°F |

10'3/16” |

10'3/8” |

10'¾” |

|

25°F |

10'3/8” |

10'¾” |

10'1-½” |

|

* Distance Represents: |

|||

“100” Expansion Track Design Data, Usage and Settings

Coefficients of thermal expansion (K) (Inches per foot per degree F) |

||

|

Steel |

Copper |

Difference |

|

.0000768 |

.0001116 |

.0000348 |

To determine expansion (or contraction) of system casing (steel) or bus bars (copper):

Expansion = K x ΔT x L

K= Constant (from table above)

L= Length (in feet)

ΔT= Temperature change (°F)

A) A straight run of “100” track has sufficient freedom of movement between copper bus bars and steel casing to accommodate an expansion or contraction of 3/8 inch of the copper bus over and above that of the steel casing. Where a Feedrail® installation will be subjected to a high or low temperature, such that the expansion or contraction of the copper bus bars (from nominal 75 °F) will exceed the steel track casing expansion or contraction by 3/8 inch, an expansion section must be used.

Example: In a 250 foot run of “100” Feedrail® track which will be subjected to a low temperature of 15 °F, the difference in contraction between the copper bus bars and the steel track casing due to the 60 °F. temperature drop from a nominal 75 °F. will be

.0000348×250 ft. x 60 °F. temp

Difference = .522 inches

Since this is in excess of the maximum of 3/8 inch (.375”) permitted, an expansion section must be used in the run.

B) It is recommended that at least one expansion track section be installed in each 400 ft. of track run, even if only minor temperature fluctuations are expected in the area in which the Feedrail® is installed.

C) Expansion track sections must be used wherever an installation is made across a building expansion joint to prevent the building movement from causing undue stresses on the Feedrail® system.

D) The “100” Expansion joint is normally made to a nominal length of 10'-0'' and is designed to operate within the limits of 9'-10'' to 10'-2'' length of the steel casing. In addition to the above movement permitted by the steel casing, the copper bus bars are permitted 50% additional movement with respect to the casing so that the normal difference in expansion or contraction between the casing and bus bars can be accommodated be the expansion joint.

E) The air temperature at the time of the actual installing of a Feedrail® system will influence the setting of a Feedrail® expansion track section. They should be set in accordance with the table in the Building Expansion Track section directly above this section.

Elevated Temperature Use Of FR-100 System

Below is a data sheet giving the U/L approved temperature usage of Feedrail® 100 systems and the temperature restrictions based on the properties of the materials used in construction of the equipment.

The U/L approval does not apply to use in ambients over 40°C (104°F.)

ELEVATED TEMPERATURE USE- RESTRICTIONS

Feedrail® FR-100 TRACK SYSTEM

RATED AMP CONTINUOUS- 150 AMP. INTERMITTANT

Feedrail® “100” is listed for its continuous ampacity rating by the Underwriters' Laboratories based on a maximum temperature rise of the bus bars of 54°F (30°C) above 104°F (40°C) ambient temperature. In order that its maximum life under continuous operating conditions might be realized, operation at elevated ambients require operation at lower ampacity as follows:

|

AMBIENT TEMPERATURE |

INTERMITTANT RATING |

AMPACITY CONTINUOUS |

% OF CONTINIOUS RATING |

|

104°F (40°C) |

150 Amps. |

100 Amps. |

100% |

|

122°F (50°C) |

127 Amps. |

85 Amps. |

85% |

|

140°F (60°C) |

87 Amps. |

58 Amps. |

58% |

|

154°F (68°C) |

37 Amps. |

25 Amps. |

25% |

In the event that the Feedrail® “100” equipment is subject to higher ambient temperature, the following information as to its operating life is offered as a guide:

A) “Rated life” based on insulation life vs. temperature is considered in excess of 100,000 hours (11.4 years) of service at rated Ampacity. (Not applicable to wearing parts such as trolley wheels and contacts).

B) Increasing the system temperature, either by increasing the ambient or the heating effect of the current through the bus bars, will shorten the life of the system by the following estimated amount:

|

SYSTEM TEMPERATURE |

LIFE EXPECTANCY % OF NORMAL |

|

176°F (80°C) |

50% |

|

194°F (90°C) |

25% |

|

212°F (100°C) |

12% |

The “100” system should not be operated so as to have any part reach 250°F (121°C). Consult factory for other conditions.

C) Factors which often accompany increased ambients (fumes, corrosion, etc.) contribute to the reduction of the service life of the equipment, often to a greater extent than temperature increases

D) Trolleys used in ambients over 104°F (40°C) should have “sealed” wheels and brush contacts, and use wire suitable for the maximum temperature expected.

* Intermittent Duty Cycle Rating based on one minute “ON”, one minute “OFF”.

Coupling Sections With Center Feed Box FR-103

Mounting End Feed Box FR-109

Mounting Dead End Cap FR-107

Installing Sectionalizing Track

Sectionalizing Track sections are used to electrically isolate parts of a track run while permitting movement of the trolleys through that portion of the track.

Sectionalizing Track sections are used to electrically isolate parts of a track run while permitting movement of the trolleys through that portion of the track.

All Sectionalizing Track sections are coupled in the same manner as Plain Track, shown in Joining Sections With Coupling Plate Set FR-102.

NOTE: The standard sections described have internal insulators of a size which do not prevent the interrupting of the current to the trolley. The current is not only maintained through the trolley but the circuits on both sides are electrically tied together through the trolley contacts as the trolley passes the sectionalizing insulator.

Other special sectionalizing track sections which are used in particular applications do break the current to the trolley. In these cases, two electrically connected trolleys must be used. They must be spaced sufficiently apart so that the contacts of one will be on the bus bars while the contacts of the other are passing the insulator. Unless connected in this manner, power will not be maintained to the trolley contacts as they cross the insulators and arcing at the trolley contacts will occur. Sectionalizing track sections must not be used as a circuit interrupting device.

Joining Sections With Coupling Plate Set FR-102

Joining Curved Track Sections

For proper assembly of the curved track, the copper bus bar splice plates and steel track connection bars are required on either the right hand or left hand end of the curved track section.

Curved track sections are furnished with separate copper bus bar splice plates and steel track connection bars. They are supplied in a bag strapped to the track section. The above illustration shows them assembled to the right hand end of the curved track section.

Before putting the copper bus bar splice plates on to the curved track section, place the loose insulator (which comes in a cloth bag fastened to the curved track section) between the curved track end and the first insulator. (See illustration above).

The below illustrations show to which end the copper bus bar splice plates and steel track connection bars must be assembled.

If the straight track to be joined to the curved track has this type of end.

The copper bus bar splice plates and steel track connection bars must be attached to the curved track to form this type of end.

After copper bus bars and steel track casings have been connected, assemble coupling plate set to track by hooking bottoms of coupling plates into slots under edges of track casings, bring plates together, insert and tighten bolts. When complete the joint will look like the above.

If the straight track to be joined to the curved track has the above type of end, the curved track must have this type of end shown below.

The connection of the straight track to the curved track, as shown above, is made without the use of the copper bus bar splice plates or the steel track connection bars. (These are used at the other end of the curved track section.)

Inserting Trolleys

|

|

|

Mounting of Crane and Hoist Type Trolleys

Trolleys for use on Cranes and Hoists (Crane and Hoist Trolleys) are equipped with a pulling bracket with chain linkage. Brackets must be attached to the hoist or crane bridge in such a manner that the chains are on the center line of the track and the bracket is parallel to the track and 2” below the track. Flexible rubber covered cables must be used for electrical connection to each trolley.

Trolleys for use on Cranes and Hoists (Crane and Hoist Trolleys) are equipped with a pulling bracket with chain linkage. Brackets must be attached to the hoist or crane bridge in such a manner that the chains are on the center line of the track and the bracket is parallel to the track and 2” below the track. Flexible rubber covered cables must be used for electrical connection to each trolley.

Mounting of Special Service Trolleys

Special Service Trolleys for use on straight track runs are equipped with a pulling bracket with chain linkage. Brackets must be attached to the hoist or crane bridge in such a manner that the chains are on the center line of the track and the bracket is parallel to the track and 3” below the track. Flexible rubber covered cables must be used for electrical connection to each trolley.

Special Service Trolleys for use on straight track runs are equipped with a pulling bracket with chain linkage. Brackets must be attached to the hoist or crane bridge in such a manner that the chains are on the center line of the track and the bracket is parallel to the track and 3” below the track. Flexible rubber covered cables must be used for electrical connection to each trolley.

Mounting Dimensions of Trolley Pulling Rackets

|

For use on Standard and Short Radius Crane and Hoist Type Trolleys without Receptacles and on Plain Transfer Type Trolleys without Receptacles. |

For use on Special Service Trolleys, on Standard and Short Radius Crane and Hoist Type Trolleys with Receptacles, on Duplex Crane and Hoist Type Trolleys, on Plain Transfer Type Trolleys with Receptacles and on Duplex Transfer Type Trolleys. |

Installation Planning

Before a Feedrail® system can be planned or an estimate of the cost prepared, the electrical and mechanical requirements that the system must meet should be known. The following outlines list the basic data needed for all applications and the additional data required for various specific applications.

Basic For All

- Describe in detail the purpose of the Feedrail® “100” system. Will it be used with existing equipment?

- What is the voltage of the available power source and type of current (A.C. or D.C.)? If A.C., is it single or three phase?

- Details about any special requirements or conditions which the installation must meet such as moisture, corrosive fumes, high or low temperatures, etc.

For Electric Cranes

- Sketch giving number, location, length of crane runways and length of bridge. Show location of building expansion joints, if any.

- How many conductors will be required on each bridge run? — How many for power? — for control? Ho w much current must each conductor carry?

- What is the maximum travel speed of the bridge? — of the hoist?

- List of the crane’s motors — main hoist, auxiliary hoist, bridge travel, trolley travel — giving the type (D.C., wound rotor, squirrel cage, etc.) of each motor and its horsepower and full-load ampere rating.

For Moving Test Lines

- Plan view sketch with dimensions showing the length of straight sections and radii of any curves. Indicate the number of outlets required. If there are any sections along the run where test current will not be required, indicate their location and extent.

- What type of equipment will be tested?

- Give weight of units to be supported by the system.

- What amperage range and what fusing arrangements will be required?

For Hanger Doors

- Sketch with dimensions to show the location and space available for the Feedrail® system. Indicate range of roof deflection due to snow loads, temperature changes, etc.

- Plan view showing exact sizes and locations of tailgates. Give location of expansion joints, if any, in the upper door guides and in the hangar roof structure. Indicate size and number of doors and pattern of door movements.

- List the number of conductors required and give voltage and amperage requirement of each. Give horsepower and full load current rating of the motors.

For Electric Hoists

- Plan view sketch of the rail system on which the hoists will travel, giving length of run and dimensions of any switches. What is the minimum distance from Feedrail® to monorail in order to clear hoist? Show location of building expansion joints.

- How many hoists will be used and what is the horsepower and full load current rating of each? Include horsepower and full load current rating of travel motors of any of the hoists that are motor propelled. What are the maximum travel speeds?

For Portable Tool and Conveyor Assembly Lines

- Sketch with dimensions showing the location and space available for the system. Show location of building expansion joint, if any.

- What type of portable tools will be used, how many, and what is the horsepower and full-load current rating of each?

- Is each tool to be fused individually? Give weight of any tools to be supported by the system.

- List any other equipment that will be operated from the Feedrail® system with the horsepower and full-load current rating of each unit.

- If power for driving any conveyors is also to be taken from the Feedrail® system, what is the horsepower and full-load current rating of each motor?

For Special Requirements

- Plan view sketch with all dimensions which are necessary to make clear the location and extent of the Feedrail® “100” system and the radii of any curves it may contain. Show the location of the power source.

- Full details about equipment which will be operated from the system, including:

- Horsepower and full-load current rating of any electrical motors.

- Weight of any equipment to be supported by the system.

- Fusing arrangements required.

- Number of outlets needed.

Preventive Maintenance

At all times Feedrail® equipment should be so protected and maintained as to be kept clean and dry.

Before the Feedrail® system is placed in operation, it should be thoroughly checked for horizontal and vertical alignment, adequate track support, and free movement of trolley travel throughout the entire track run. All track, bus bar and feed connections should be mechanically tight. The system should be checked for possible grounds or short circuits. Any paint, grease, or other foreign matter accumulated during construction should be removed from the bus bars, insulation and track interior. Blow out all dust and other loose particles from inside the track.

Expansion sections, when used, must be properly adjusted, located and supported in accordance with installation instructions. Check bus bars and casing for accurate alignment.

Feedrail® is both an electrical and a moving mechanical system and therefore should be included as a part of your Preventive Maintenance Program.

Electrical maintenance requires:

- Keeping the System dry and clean to prevent electrical leakage or “shorts” across the insulation.

- Maintaining electrical continuity by keeping bus bar contact surfaces clean and joints tight.

Mechanical maintenance requires:

- Preventing excessive wear

- Replacing parts showing excessive wear.

The following Preventive Maintenance procedure, periodically performed, is recommended:

- Remove, thoroughly clean all trolleys and lubricate the wheels. Feedrail® recommends Grade #1 Bearing Grease. This is softer grease than #2 and allows the grease to penetrate the bearings easier. Inspect contacts for excessive wear. Replace worn wheels and contacts.

- Clean bus bars with Feedrail® Bus Bar Cleaner.

- Blow out all foreign particles which have accumulated inside the track.

- Check trolleys for free movement within the track.

- Check all track supports, track joints, bus bar and feed connections for tightness.

This procedure should be repeated at regular intervals, consistent with the severity of the operations and usage of the system. Plants operating two or three shifts will require more frequent inspection of the Feedrail® equipment.

Feedrail® is not normally recommended for installations subject to vibration, frequent electrical overload, corrosive fumes and other abnormal conditions. However, should such conditions exist, more frequent inspection and main– tenance will be required.

Before additional electrical loads are added to the system it should be determined that sufficient capacity is available.

Basic Dimensions/Mounting Methods of Feedrail® ‘100’ Assembly

Examples of the methods commonly used for mounting Feedrail® “100” systems track runs are shown. These methods can be used in existing plants as well as in new buildings. Engineers and contractors will readily be able to devise other methods to suit special installations. In every case the mounting should be designed to insure a rigid installation in both horizontal and vertical alignment.

As an aid in planning mountings, the basic dimensions of the “100” systems are shown. These are offered as a guide only.

Typical Specification

The Trolley Busway System (Crane and Hoist Electrification System) shall be of metal enclosed type with internally track supported trolleys as manufactured by:

Genuine Feedrail®

Industrial Products

The System shall have a voltage rating of 600 Volts A.C. or 250 Volts D.C. (2 pole) (3 pole) and a continuous current carrying capacity of 100 Amperes per Pole: (When used as a Crane and Hoist Electrification System, the System shall be rated at 100 Amperes continuous service and 150 Amperes intermittent service). The full current carrying capacity of the system shall be maintained throughout.

The System shall permit longitudinal movement of the housing and bus bars, independent of each other, in order to allow for unequal expansion and contraction as a result of temperature changes.

The System shall consist of standardized, interchangeable, Feedrail® units — track sections, coupling sets, dead end caps, track hangers and power takeoff trolleys, as called for on the plans.

Track sections shall be pressed 13 gauge zinc-coated sheet steel enclosures having a continuous slot in the bottom. Rolled or drawn copper bus bars, capable of carrying 100 Amperes per pole continuously without overheating, shall be mounted within the steel enclosure on arc-resistant insulators.

Door track sections shall include two hinged doors in the bottom for insertion and removal of trolleys. Door openings shall have a mechanical polarization to insure proper polarity of the trolleys.

Track supported trolleys shall be Cat. No.__________________________ as listed in the Feedrail® Catalog. They shall have a zinc-plated sheet steel chassis with metal wheels for support. Horizontal guide wheels shall run in the slot of the Feedrail® track to prevent slewing and maintain alignment. Spring-loaded roller, (or brush) contacts shall be mounted on arc-resistant insulation. When inserted in Feedrail® track, the contacts shall align with the bus bars at all times.

Trolleys shall be mechanically polarized with respect to door track sections.

Build Your Feedrail FR100 Series Trolley Service System

All of the components you’ll need to build a brand new Feedrail FR100 Series system have been organized below by category. It is recommended that you start with Track Sections and work your way through each category in the order they’re presented. If you have any questions, please contact us and one of our highly trained Feedrail specialists will respond shortly.

Track Sections |

Track Accessories & Hangers |

Trolleys |

Track & Busway Cleaning Tools |

Ever-Lok Wiring Devices |

Replacement Parts |

Shop for Feedrail FR100 Series Trolley Service System Components, Parts & Accessories

All components, parts and accessories for the Feedrail FR100 Series Trolley Service System can be found below. Use the product filter menu to narrow your search.

Track Sections

Feedrail 10’ Straight Track – 3 Pole, 100 Amp |

||

|

Item Number: FR100 Styles: W00319A 10 foot straight track section. 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$1040.00/EA

|

Feedrail 5’ Straight Track – 3 Pole, 100 Amp |

||

|

Item Number: FR1005 Styles: W00319A5 5 foot straight track section. 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$1040.00/EA

|

Feedrail 10’ Straight Track with Door – 3 Pole, 100 Amp |

||

|

Item Number: FR101 Styles: W10381A 10 foot straight track section with trolley door. 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$1535.00/EA

|

Feedrail Curved Track - 2' 6" Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR115 Styles: S16837A Curved track, 2' 6" radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$5930.00/EA

|

Feedrail Curved Track - 3' Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR113 Styles: FR113 Curved track, 3' radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$5995.00/EA

|

Feedrail Curved Track - 3' 6" Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR116 Styles: FR116 Curved track, 3' 6" radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$5772.00/EA

|

Feedrail Curved Track - 4' Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR117 Styles: S16840A Curved track, 4' radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$5820.00/EA

|

Feedrail Curved Track - 4' 6" Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR114 Styles: FR114 Curved track, 4' 6" radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$5883.00/EA

|

Feedrail Curved Track - 5' Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR118 Styles: S16842A Curved track, 5' radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$5942.00/EA

|

Feedrail Curved Track - 5' 6" Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR111 Styles: FR111 Curved track, 5' 6" radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$6011.00/EA

|

Feedrail Curved Track - 6' Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR119 Styles: FR119 Curved track, 6' radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$6069.00/EA

|

Feedrail Curved Track - 6' 6" Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR121 Styles: S16845A Curved track, 6' 6" radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$6440.00/EA

|

Feedrail Curved Track - 7' Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR120 Styles: FR120 Curved track, 7' radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$6265.00/EA

|

Feedrail Curved Track - 7' 6" Radius, 3 Pole, 100 Amp |

||

|

Item Number: FR112 Styles: FR112 Curved track, 7' 6" radius (to center line). 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$6276.00/EA

|

Feedrail 10' Sectionalizing Track - 3 Pole, 100 Amp |

||

|

Item Number: FR147 Styles: U10624A 10 foot sectionalizing track. 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$3225.00/EA

|

Feedrail 10' Sectionalizing Track with Door - 3 Pole, 100 Amp |

||

|

Item Number: FR148 Styles: U10625A 10 foot sectionalizing track with trolley door. 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$4485.00/EA

|

Feedrail 10' Expansion Track - 3 Pole, 100 Amp |

||

|

Item Number: FR155 Styles: W09931A 10 foot expansion track. 3 pole, 100 amp, 600 volt AC / 250 volt DC. Fits Feedrail FR100. |

$14435.00/EA

|

Feedrail 10' Transfer Track Section - 3 Pole, 100 Amp |

||

|

Item Number: FR195 Styles: FR195 10 foot transfer track, two ends flared. For FR100 Series (Feedrail(R) '100'). Note: Sections complete with bus bars and a center feed box FR-103. 3 pole, 100 amp, 600 volt AC / 250 volt DC. |

$6440.00/EA

|

Feedrail 10' Transfer Track Section with Door - 3 Pole, 100 Amp |

||

|

Item Number: FR196 Styles: FR196 10 foot transfer track with trolley door, two ends flared. For FR100 Series (Feedrail(R) '100'). Note: Sections complete with bus bars and a center feed box FR-103. 3 pole, 100 amp, 600 volt AC / 250 volt DC. |

$7775.00/EA

|

Feedrail 10' Transfer Track without Bus Bars, One End Flared |

||

|

Item Number: FR132 Styles: FR132 10' transfer track, one end flared, without bus bars. For FR100 Series (Feedrail(R) '100'). |

$1856.00/EA

|

Feedrail 10' Transfer Track without Bus Bars, with Door, One End Flared |

||

|

Item Number: FR133 Styles: FR133 10' transfer track, one end flared, without bus bars, with trolley door. For FR100 Series (Feedrail(R) '100'). |

$2673.00/EA

|

Feedrail 10' Transfer Track without Bus Bars, Two Ends Flared |

||

|

Item Number: FR142 Styles: FR142 10' transfer track, two ends flared, without bus bars, with trolley door. For FR100 Series (Feedrail(R) '100'). |

$2254.00/EA

|

Feedrail 10' Transfer Track without Bus Bars, with Door, Two Ends Flared |

||

|

Item Number: FR143 Styles: FR143 10' transfer track, two ends flared, without bus bars, with trolley door. For FR100 Series (Feedrail(R) '100'). |

$3071.00/EA

|

Feedrail 10' Transfer Track with Offset Bus Bar Ends, One End Flared - 3 Pole, 100 Amp |

||

|

Item Number: FR185 Styles: W11261A 10 foot transfer track, one end flared with offset bus bar ends. For FR100 Series (Feedrail(R) '100'). Note: Sections complete with bus bars. 3 pole, 100 amp. |

$3955.00/EA

|

Feedrail 10' Transfer Track with Offset Bus Bar Ends & Door, One End Flared - 3 Pole, 100 Amp |

||

|

Item Number: FR186 Styles: FR186 10 foot transfer track with trolley door, one end flared with offset bus bar ends. For FR100 Series (Feedrail(R) '100'). Note: Sections complete with bus bars. 3 pole, 100 amp. |

$5155.00/EA

|

Feedrail 10' Transfer Track, One End Flared with Plain Bus Bar Ends - 3 Pole, 100 Amp |

||

|

Item Number: FR187 Styles: W11260A 10 foot transfer track, one end flared with plain bus bar ends. For FR100 Series (Feedrail(R) '100'). Note: Sections complete with bus bars. |

$3945.00/EA

|

Feedrail 10' Transfer Track with Door, One End Flared with Plain Bus Bar Ends - 3 Pole, 100 Amp |

||

|

Item Number: FR188 Styles: FR188 10 foot transfer track with door, one end flared with plain bus bar ends. For FR100 Series (Feedrail(R) '100'). Note: Sections complete with bus bars. |

$5155.00/EA

|

Feedrail Coupling Plate Set for FR100 Series (Feedrail '100') |

||

|

Item Number: FR102 Styles: U10318 Set of two heavy gauge pressed steel plates serves as a coupling for track sections and as a hanger for attaching to supporting members. Removable snap on covers permit ready access to the bus bar joints. |

$151.00/EA

|

Feedrail Dead End Cap for FR100 Series (Feedrail '100') |

||

|

Item Number: FR107 Styles: U00278 Set of two heavy gauge pressed steel plates and box for closing the end of a track run. Also serves as a hanger fo attaching to supporting members. Include a trolly stop. |

$198.00/EA

|

Feedrail Center Feed Box for FR100 Series (Feedrail '100') - 3 Pole, 100 Amp |

||

|

Item Number: FR103 Styles: U00213P Set of two heavy gauge pressed steel plates, box and covers, through which electrical connection to the power supply is made between any two track sections. Serves as a track coupling and hanger for attaching supporting members. Has concentric knockouts for 3/4", 1", 1-1/4" or 1-1/2" conduit in the top. complete with pressure type terminals accommodating No. 14 to 0 stranded wire. |

$1220.00/EA

|

Feedrail Reversible End Feed Box for FR100 Series (Feedrail '100') - 3 Pole, 100 Amp |

||

|

Item Number: FR109 Styles: U13809P Set of two heavy gauge pressed steel plates and a two piece box through which electrical connection to the power supply can be made at the end of a track run. Reversible box permits conduit connection at top, bottom of end. Has concentric knockouts for 3/4", 1', 1-1/4" or 1-1/2" conduit. Also serves as a hanger for attaching track to supporting members. Complete with pressure type terminals accommodating No. 14 to 0 stranded wire. |

$693.00/EA

|

Feedrail Auxilliary Track Hanger Set |

||

|

Item Number: FR140 Styles: S00186P Heavy gauge pressed steel plates for intermediate mounting of track sections to supporting members. Fits over top of straight track housing rib at any of the insulator bolting points. Complete with 3/8" mounting bolt. |

$26.00/EA

|

Feedrail Transfer Point Hanger Set for FR100 Series (Feedrail '100') |

||

|

Item Number: FR124 Styles: U03543 Set of two heavy gauge pressed steel plates formed to match flared ends of transfer sections. Use as hanger for attaching to supporting mebers at open end of transfer track sections. |

$115.00/EA

|

Electro-Rail Clevis Support for Tie Rod Installations |

||

|

Item Number: 12283 Styles: ER105 Clevis support for tie rod applications. Malleable iron, with 3/8" cross bolt and 3/8"-16 tapped hole for tie rod. Must be used in conjunction with FRS-124 and FRS-105 track hangers. |

$13.00/EA $9.10/EA 30% discount |

Feedrail Single Trolley, Non-Fusible with Roller Contacts - 3 Pole, 20 Amp |

||

|

Item Number: FR724 Styles: W20008A Single trolley, non-fusible, for FR100 Series (Feedrail "100"). 20 amps, 3 poles, 600 VAC - 250 VDC, roller contact. |

$515.00/EA

|

Feedrail Single Trolley, Non-Fusible with Brush Contacts - 3 Pole, 30 Amp |

||

|

Item Number: FR780 Styles: W19225A Single trolley, non-fusible, for FR100 Series (Feedrail "100"). 30 amps, 3 poles, 600 VAC - 250 VDC, brush contact. |

$498.00/EA

|

Feedrail Duplex Trolley, Non-Fusible with Roller Contacts - 3 Pole, 40 Amp |

||

|

Item Number: FR727 Styles: W20166E Duplex trolley, non-fusible, for FR100 Series (Feedrail "100"). 40 amps, 3 poles, 600 VAC - 250 VDC, roller contact. |

$1428.00/EA

|

Feedrail Duplex Trolley, Non-Fusible with Brush Contacts - 3 Pole, 40 Amp |

||

|

Item Number: FR782 Styles: W20166A Duplex trolley, non-fusible, for FR100 Series (Feedrail "100"). 60 amps, 3 poles, 600 VAC - 250 VDC, brush contact. |

$1438.00/EA

|

Feedrail Trolley with Hanger Cabinets - 3 Pole, 20 Amp |

||

|

Item Number: FR705 Styles: W20930E Trolley with hanger cabinets for FR100 Series (Feedrail "100"). 20 amps, 3 poles, 600 VAC - 250 VDC, roller contact. |

$1115.00/EA

|

Feedrail Trolley with Hanger Cabinets - 3 Pole, 30 Amp |

||

|

Item Number: FR785 Styles: W20930A Trolley with hanger cabinets for FR100 Series (Feedrail "100"). 30 amps, 3 poles, 600 VAC - 250 VDC, brush contact. |

$1113.00/EA

|

Feedrail Fusible Trolley with Beveled Cabinets and 30 Ampere Recepticle - 3 Pole, 30 Amp |

||

|

Item Number: FR870 Styles: W20217C Trolley with beveled cabinets, fusible, with 30 ampere recepticle. For FR100 Series (Feedrail "100"). 3 poles, 250 A.C. - 250 D.C., 30 amps. Brush contact and dead front fuse block. |

$2509.00/EA

|

Feedrail Non-Fusible Trolley with Box Cabinet and Cable Clamp - 3 Pole, 20 Amp |

||

|

Item Number: FR741 Styles: W20222N Trolley with box cabinet, non-fusible, without recepticle, with cable clamp. For FR100 Series (Feedrail "100"). 3 poles, 20 amps, 600 VAC - 250 VDC. Roller contact. |

$1176.00/EA

|

Feedrail Non-Fusible Trolley with Box Cabinet and Cable Clamp - 3 Pole, 30 Amp |

||

|

Item Number: FR784 Styles: W20222A Trolley with box cabinet, non-fusible, without recepticle, with cable clamp. For FR100 Series (Feedrail "100"). 3 poles, 30 amps, 600 VAC - 250 VDC. Brush contact. |

$1181.00/EA

|

Feedrail Fusible Trolley with Box Cabinet and Cable Clamp - 3 Pole, 20 Amp |

||

|

Item Number: FR743 Styles: W20783C Trolley with box cabinet, fusible, without recepticle, with cable clamp. For FR100 Series (Feedrail "100"). 3 poles, 20 amps, 600 VAC - 250 VDC. Roller contact and open front fuse block. |

$1565.00/EA

|

Feedrail Fusible Trolley with Box Cabinet and Cable Clamp - 3 Pole, 30 Amp |

||

|

Item Number: FR788 Styles: W20783D Trolley with box cabinet, fusible, without recepticle, with cable clamp. For FR100 Series (Feedrail "100"). 3 poles, 30 amps, 600 VAC - 250 VDC. Brush contact and open front fuse block. |

$1533.00/EA

|

Feedrail Crane and Hoist Single Trolley, Non-Fusible - 3 Pole, 30 Amp |

||

|

Item Number: FR706 Styles: W19225C Crane and hoist trolley for FR100 Series (Feedrail "100"). Single trolley, non fusible. 3 poles, 30 amps. Brush contact. Voltages - 220 VAC: 7-1/2HP, 440 VAC: 15HP and 550 VAC: 20HP. Note: Not for use with Transfer Track. |

$656.00/EA

|

Feedrail Crane and Hoist Single Trolley, Non-Fusible with Receptacle - 3 Pole, 30 Amp |

||

|

Item Number: FR706-8304 Styles: W20148C Crane and hoist trolley for FR100 Series (Feedrail "100"). Single trolley, non fusible, wired with a 30 amp recpetacle. 3 poles, 30 amps. Brush contact. Voltages - 220 VAC: 7-1/2HP, 440 VAC: 15HP and 550 VAC: 20HP. Note: Not for use with Transfer Track. |

$1989.00/EA

|

Feedrail Crane and Hoist Duplex Trolley, Non-Fusible - 3 Pole, 60 Amp |

||

|

Item Number: FR706D Styles: W20163A Crane and hoist trolley for FR100 Series (Feedrail "100"). Duplex trolley, non fusible. 3 poles, 60 amps. Brush contact. Voltages - 220 VAC: 15HP, 440 VAC: 30-HP and 550 VAC: 40-HP. Note: Not for use with Transfer Track. |

$2257.00/EA

|

Feedrail Single Transfer Type Trolley - 3 Pole, 30 Amp |

||

|

Item Number: FR774 Styles: W20188A Transfer type single trolley - non fusible, for use on track runs which include transfer gaps. 3 pole, 30 amp. |

$924.00/EA

|

Feedrail Single Transfer Type Trolley with Receptacle - 3 Pole, 30 Amp |

||

|

Item Number: FR774-8304 Styles: FR774-8304 Transfer type single trolley - non -fusible, with receptacle, Wired complete with Ever-Lok® 30 Ampere receptacle. 3 pole, 30 amp. |

$2268.00/EA

|

Feedrail Duplex Transfer Type Trolley - 3 Pole, 30 Amp |

||

|

Item Number: FR774D Styles: W20212A Transfer type duplex trolley - non-fusible, for use on track runs which include transfer gaps where current must be maintained while crossing transfer points. These trolleys must be used on motor propelled hoists to provide continuous current while crossing transfer points. |

$2215.00/EA

|

Feedrail Duplex Transfer Type Trolley with Receptacle - 3 Pole, 30 Amp |

||

|

Item Number: FR774D-8304 Styles: W20213C Transfer type duplex trolley - non-fusible, with receptacle, wired complete with Ever-Lok® 30 Ampere receptacle. 3 pole, 30 amp. |

$2855.00/EA

|

Feedrail 100 Ampere Special Service Trolley - 3 Pole, 100 Amp |

||

|

Item Number: FR75 Styles: W05893B Typical of Feedrail's advanced engineering design, this single unit trolley combines all the essential features of the standard trolley series with the special requirements of high power full rated take-off. It is ideal for heavy tonnage travelling cranes, hoists and similar equipment. 3 pole, 100 amp. |

$5725.00/EA

|

Feedrail Dust Remover with Bristle Brushes for FR100 Series Trolley Service |

||

|

Item Number: FR76 Styles: U06298 Dust remover with bristle brushes for FR100 series track. |

$1040.00/EA

|

Feedrail Bus Bar Cleaner with Cleaning Stones for FR100 Series Trolley Service |

||

|

Item Number: FR77 Styles: U06350 Bus bar cleaner with cleaning stones for FR100 series track. |

$1480.00/EA

|

Ever-Lok® Wiring Device, Unfused, for Feedrail FR100 Series |

||

|

Item Number: 8314S Styles: 8314S Used for connecting tools and other equipment to Feedrail® trolleys. Ever-Lok® Wiring Device, make plug, unfused. For FR100 Series. 30 amps, 600 volts AC, 250 volts DC. |

$192.00/EA

|

Feedrail 10' Bus Bar with Screws, 100 Amp, for Feedrail FR100 Series |

||

|

Item Number: S16711 Styles: 90-1 Bus bar with screws, 10 foot, for FR100 Series (Feedrail® '100') |

$331.00/PK

|

Feedrail Bus Bar Screw (#8-32 X 1/4" FHMS SPINL CU/P) |

||

|

Item Number: S16719A Styles: S16719A Feedrail Bus Bar Screw (#8-32 X 1/4" FHMS SPINL CU/P) |

$2.00/EA

|

Feedrail Bus Bar Insulator for Straight Track |

||

|

Item Number: U21145 Styles: U21145 Feedrail bus bar insulator for straight track sections. |

$39.00/EA

|

Feedrail Bus Bar Offset End Insulator |

||

|

Item Number: S22165 Styles: S22165 Feedrail bus bar offset end insulator. |

$63.00/EA

|

Feedrail Bus Bar Insulator for Curved Track |

||

|

Item Number: U11972 Styles: 55-27 Feedrail bus bar insulator for curved track sections. |

$118.00/EA

|

Feedrail Bus Bar Insulator for Either Side of Doors |

||

|

Item Number: T12058 Styles: T00220P Feedrail bus bbar insulator for either side of doors. |

$120.00/EA

|

Feedrail Track Connection Bar with Screws, for FR100, FH and FM Series |

||

|

Item Number: S19321 Styles: 90-6 Feedrail track connection bar with screws, for FR100, FH and FM Series. |

$62.00/EA

|

Feedrail Connection Bar Fastening Screws for Bottom of Track Casing |

||

|

Item Number: 301269 Styles: 301269 Connection bar fastening screws for bottom of track casing for FH Series (Feedrail® 'HD') and FR100 Series (Feedrail® '100'). |

$5.00/EA

|

Feedrail Replacement Door Hinge Assembly for FR100 and FX Series |

||

|

Item Number: W10379 Styles: 85-25 Feedrail replacement door hinge assembly for FX Series (Multi-Conductor Trolley Service 4 and 5 Pole) and FR100 Series (Feedrail® '100'). Two required for each door section. |

$191.00/EA

|

Feedrail Sectionalizing Insulator |

||

|

Item Number: S16907 Styles: 55-21 Feedrail sectionalizing insulator. |

$604.00/EA

|

Feedrail Sectionalizing Insulator Full Interuptor with 12 Screws |

||

|

Item Number: S16906 Styles: 55-15 Sectionalizing insulator full interuptor with 12 screws. |

$728.00/EA

|

Feedrail Nose Insulator with Screws |

||

|

Item Number: S16908 Styles: 55-34 Nose insulator with screws. |

$582.00/EA

|

Feedrail Nose Insulator with Screws |

||

|

Item Number: S16918 Styles: 55-33 Nose insulator with screws. |

$364.00/EA

|

Feedrail Transfer Nose Insulator with Screws |

||

|

Item Number: S21700 Styles: S21700 Feedrail transfer nose insulator with screws. |

$568.00/EA

|

Feedrail Transfer Nose Insulator with Inserts |

||

|

Item Number: W11732 Styles: FR55-28 Feedrail transfer nose insulator with inserts. |

$305.00/EA

|

Feedrail Dust Remover Bristle Brush |

||

|

Item Number: T06301P Styles: 15-84 Feedrail dust remover bristle brush. |

$269.00/EA

|

Feedrail Cleaner Stone Assembly (1-Pole) |

||

|

Item Number: T06390P Styles: 15-86 Feedrail cleaner stone assembly, one pole only. |

$65.00/EA

|

Feeedrail Trolley Body Assembly with Roller Contacts - 3 Pole, 20 Amp |

||

|

Item Number: U20019C Styles: 10-50 Feeedrail 3 pole, 20 amp trolley body assembly with roller contacts. |

$451.00/EA

|

Feedrail X Roller Contact Assembly, Outside, 20 Amp |

||

|

Item Number: S20541X Styles: S20541X Feedrail X roller contact assembly, outside, 20 amp. |

$118.00/EA

|

Feedrail Y Roller Contact Assembly, Center, 20 Amp |

||

|

Item Number: S20541Y Styles: S20541Y Feedrail Y roller contact assembly, center, 20 amp. |

$132.00/EA

|

Feedrail Z Roller Contact Assembly, Outside, 20 Amp |

||

|

Item Number: S20541Z Styles: S20541Z Feedrail Z roller contact assembly, outside, 20 amp. |

$119.00/EA

|

Feedrail Trolley Body Assembly with Copper Graphite Brush Contacts - 3 Pole, 30 Amp |

||

|

Item Number: U16538C Styles: 10-46 3 pole trolley body assembly with copper graphite brush contacts for FR100 Series (Feedrail® '100'). 3 poles, 30 amps. |

$417.00/EA

|

Feedrail X CGB Contact Assembly, Outside, 30 Amp |

||

|

Item Number: S20539X Styles: 15-211 Feedrail X copper graphite brush contact assembly, outside, 30 amp. |

$106.00/EA

|

Feedrail Y CGB Contact Assembly, Outside, 30 Amp |

||

|

Item Number: S20539Y Styles: 15-212 Feedrail X copper graphite brush contact assembly, outside, 30 amp. |

$121.00/EA

|

Feedrail Z CGB Contact Assembly, Outside, 30 Amp |

||

|

Item Number: S20539Z Styles: 15-213 Feedrail Z copper graphite brush contact assembly, outside, 30 amp. |

$109.00/EA

|

Feedrail Contact Cap with Screws |

||

|

Item Number: S20527 Styles: S20527 Feedrail contact cap with screws. |

$56.00/EA

|

Feedrail Chassis Assembly for FR100 Series |

||

|

Item Number: T16491 Styles: 20-144 Feedrail chassis assembly for FR100 Series. |

$349.00/EA

|

Feedrail Transfer Type Chassis Assembly for FR100 Series |

||

|

Item Number: T20007 Styles: 20-145 Chassis assembly, transfer type, for FR100 Series (Feedrail® '100'). |

$544.00/EA

|

Feedrail Trolley Body with Inserts, for FR100 Series |

||

|

Item Number: W15817 Styles: W15817 Trolley body only, with inserts, for FR100 Series (Feedrail® '100'). |

$185.00/EA

|

Feedrail Trolley Body Body Mounting Screw for FR100 Series |

||

|

Item Number: 309484 Styles: 309484 Trolley Body Body Mounting Screw for FR100 series. (10-32 X 3/8 SLOT FLAT M/S UNDERCUT) |

$2.15/EA

|

Feedrail Insulating Liner for FR100 Series |

||

|

Item Number: S20031 Styles: 55-72 Insulating liner for FR100 Series (Feedrail® '100'). |

$25.00/EA

|

Feedrail Undercarriage Wheel Assembly for FR100, FM and FX Series |

||

|

Item Number: T05714 Styles: 20-38 Undercarriage wheel assembly for FR100, FM and FX Series. |

$81.00/EA

|

Feedrail Single Trolly Bracket with 1-1/16" Hole for FR100, FM and FX Series |

||

|

Item Number: T09690 Styles: 20-77 Single trolly bracket, 1-1/16" hole for FR100, FM and FX Series. |

$40.00/EA

|

Feedrail Single Trolly Bracket and Cable Clamp Assembly with Lug for FR100, FM and FX Series |

||

|

Item Number: T09942 Styles: T09942 Single trolly bracket and cable clamp assembly with lug for FR100, FM and FX Series. |

$61.00/EA

|

Feedrail Duplex Trolley Bracket with 7/8" Hole, for FR100 Series |

||

|

Item Number: T09692 Styles: T09692 Duplex trolley bracket, 7/8" dia. hole, for FR100 Series (Feedrail® '100'). |

$34.00/EA

|

Feedrail Duplex Trolley Bracket with 1/16" Hole for FR100 Series |

||

|

Item Number: T09936 Styles: 20-75 Duplex trolley bracket, 1/16" dia. hole, for FR100 Series (Feedrail® '100'). |

$65.00/EA

|

Feedrail Duplex Trolley Bracket and Bushing Assembly for FR100, FM and FX Series |

||

|

Item Number: T09944 Styles: 65-25 Duplex trolley bracket and bushing assembly for FR100, FM and FX Series. |

$133.00/EA

|

Feedrail Pulling Bracket for Cabinet Type Trolleys with Chains, for FR100, FM and FX Series |

||

|

Item Number: U09740 Styles: 20-74 Pulling bracket for cabinet type trolleys with chains for FR100, FM and FX Series. |

$104.00/EA

|

Feedrail Pulling Bracket for Non-Cabinet Type Trolleys with Chains, for FR100, FM and FX Series |

||

|

Item Number: U10056 Styles: U10056 Pulling bracket for non-cabinet type trolleys with chains for FR100, FM and FX Series. |

$104.00/EA

|

Feedrail Universal Joint Assembly for FR100 Series Duplex Trolleys |

||

|

Item Number: T06488 Styles: 20-51 Universal joint assembly for duplex trolleys, for FR100 Series (Feedrail® '100'). |

$166.00/EA

|

Feedrail Swivel Joint Assembly for Crane & Hoist and Transfer Type Duplex Trolleys |

||

|

Item Number: S02979 Styles: S02979 Swivel joint assembly for crane & hoist and transfer type duplex trolleys, for FR100 Series (Feedrail® '100'). |

$44.00/EA

|

Feedrail X Silver Tungsten Brush Contact Assembly for FR100 Series - 100 Amp |

||

|

Item Number: T05895 Styles: 15-77X "X" silver tungsten brush contact assembly for FR100 Series (Feedrail® '100'), 100 amp. |

$1345.00/EA

|

Feedrail Y Silver Tungsten Brush Contact Assembly for FR100 Series - 100 Amp |

||

|

Item Number: T05896 Styles: 15-78Y "Y" silver tungsten brush contact assembly for FR100 Series (Feedrail® '100'), 100 amp. |

$1393.00/EA

|

Current Carrying Capacity

Current Carrying Capacity Track

Track