Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Overhead Electrification Systems for Movable Trolley or Stationary Plug-In Service

General Information:Feedrail® systems are capable of providing multi-purpose trolleys or stationary plug-ins for installations requiring a source of electrical power which can be reconfigured without rewiring. These systems provide moveable outlets for electrical power along their entire length. The systems are especially suited for use where conventional wire systems would be cumbersome and costly. Plug-in Jacks with stationary power take-offs, are available for all Feedrail® systems. The busway-supported outlets called “trolleys” (Feedrail® 60 system only) make contact with the enclosed bus bars and provide a continuous moveable connection for electrical devices. The trolleys are easily inserted and removed through door-busway sections. As additional outlets are needed, trolleys (Feedrail® 60 System only) or stationary plug-ins can be quickly and efficiently inserted, their numbers being limited only by the current-carrying capacity of the busway and the capacity of each outlet. Reliable design assures uniform contact pressure, limiting work stoppages due to electrical and mechanical interruptions in supplying power. Advantages of these systems include low installation costs with complete re-usability; ease of adding outlets as required; electrical and personnel safety; compactness; dependability and minimum maintenance expense. All “busway (track) sections” are factory assembled for ease in handling and rapid installation. No special tools are required. Systems are designed for indoor use in non-hazardous, non-corrosive, dry atmosphere. UL & CSA ListedFeedrail® is listed by Underwriter's Laboratories, Inc. (U.L.) under BUSWAYS AND ASSOCIATED FITTINGS (File E11348 for Feedrail® / File E165922 for Electro-Rail® ) and as a CRANE AND HOIST ELECTRIFICATION SYSTEM (File E31188 for Feedrail® ). Feedrail® is also listed by the Canadian Standards Association (C.S.A.) under WIREWAYS AND BUSWAYS (File LL-7907 for Feedrail® / File LL 103287-1 for Electro-Rail® ).

|

Basic Information:

More Information:

This short video (no sound) shows the basic components and set up for the Feedrail® FRS100, 200 & 300 Series. |

FRS100 & FRS200 Series Service — Design and Construction

Current Carrying Capacity

(Click image for full-size view)Track Rating: 60 amps continuous

Trolley Rating: 5, 15, 20 or 30 amps continuous

Plug-In Jack Rating: 15 amps continuous.

Voltage

300 VAC, 300 VDC

Track

Track sections consist of a one-piece streamlined 18-gauge zinc coated steel housing and the enclosed current carrying bus bars and insulators, all factory assembled in convenient lengths ready for easy, fool-proof installation on the job. No special tools required. The lower horizontal portions of the housing serve as smooth, rigid runways for the trolleys.

FRS100 & FRS200 Series Track sections are available in various types — Straight, Door, Sectionalizing and Transfer Track sections.

Bus bars are of hard-drawn copper. They are amply proportioned to carry the specified current of 60 amperes per pole continuously, 90 amperes per pole intermittently, without overheating. Bus bar connectors assure full current carrying capacity across the joints without interfering with the free travel of the trolley contacts.

Insulators are made of a high insulating and arc-resistant material. The are locked in place on 9-5/8” centers.

Track Supports

Steel clamp type track hangers for supporting track sections from strap or rod. Track may be supported on up to 10' centers at track joints when used with Duplex Track Hangers. Additional track hangers can be attached at intermediate points. Track should be supported by a minimum of two track hangers per section.

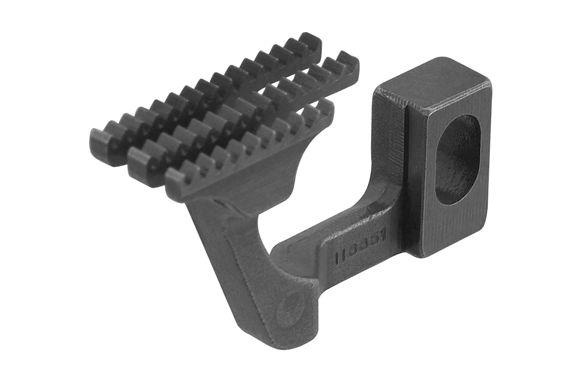

Trolleys

Feedrail® trolleys are designed to provide stable clean power; arcing and hot spots are essentially eliminated. Stable clean power is required for trouble free operation of today’s computer controlled equipment and machinery.

Trolleys are available in both fusible and non-fusible types.

All Feedrail® 2 and 3 Pole trolleys have a chassis-insulator contact assembly. The chassis is of heavy gauge steel. The trolley wheels and guide wheels are of the ball bearing type.

Horizontally mounted ball bearing guide wheels prevent slewing when running in the track. A substantially proportioned insulator block combines the best insulating properties with high arc resistance.

FRS100 and FRS200 Series 2 and 3 Pole trolleys are furnished with three types of contacts:

- COPPER GRAPHITE ROLLER CONTACTS for intermittent movement no in excess of 150 feet per minute

- COPPER GRAPHITE BRUSH CONTACTS for movement up to 250 feet per minute

- BRONZE BRUSH CONTACTS for stationary service

A polarizing tab on the chassis operating in conjunction with a stop in the door track section permits insertion of the trolleys only one way. Equipment grounding may be made through the trolleys. Weights in excess of 20 pounds per trolley are not recommended for moving applications.

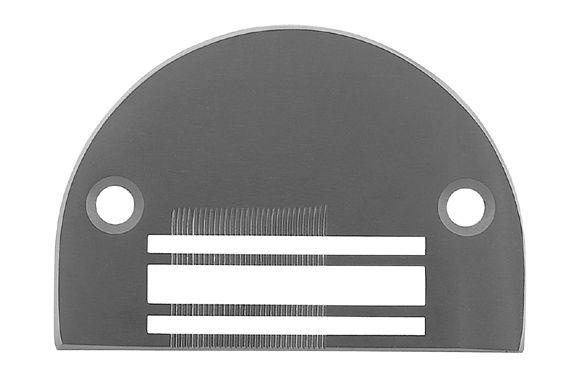

Plug-In Jacks

Plug-in Jacks are designed for applications where the mobility of trolleys is not required, such as in some sewing rooms or for connecting lighting fixtures and small tools to Feedrail® track. They can be inserted into the track section at any point. A quarter turn after insertion makes electrical contact with the bus bars and locks the jack in place.

Grounding

For the safety of personnel, the track casings of the Feedrail® system may be used as an equipment grounding conductor for grounding equipment through the individual trolleys and plug-in jacks.

Equipment grounding may be made by using the screw on the underside of the trolley chassis or plug-in jacks or on trolleys or jacks having cabinets of boxes by using the grounding screw within the box. Track housing must be grounded through conduit or other suitable means.

FRS100 & FRS200 Series systems are designed for indoor service in essentially dry locations. Feedrail® systems are electrified tracks in which the current carrying components are enclosed in protective steel housings. Smooth riding internally track supporting trolleys or plug-in jacks take off current and provide electric power for crane and hoist or other types of electrification systems.

The FRS100 & FRS200 Series systems have been specifically developed to provide safe electrification for sewing machines, cloth cutting machines, cloth laying and inspection machines, silk screen printing and drying machines, monorail hoists, light duty cranes and stackers, book binding machines, portable tools on assembly and production lines, radio, TV and appliance test lines, lights for offices, stores, factories, etc.

The FRS100 and FRS200 Series systems are made up of standardized units, factory assembled for fast, complete installation without on-site fabrications. These 2 and 3 pole systems may be used to provide both power and control. They are ideally suited for use on control circuits where other standard Feedrail® systems supply heavier electrification requirements.

Bus Bar Arrangement

Typical Electrical Systems for Various Applications

| Applications | Electrical System | Connections-Grounding |

|---|---|---|

For Single Phase

|

Single Phase 2P, 3W 110V, 208V, 220V or 277V Equipment ground wire thru casing |

|

| Single Phase 2P, 3W 110V, 208V, 220V or 220V with one bus for equipment ground |

|

|

| Single Phase 3P, 4W 110V & 220V Equipment ground wire thru casing |

|

|

Applications |

Electrical System |

Connections-Grounding |

For Three Phase

|

Three Phase 3P, 4W 208V or 220V Equipment ground wire thru casing |

|

Installation Planning

Before a Feedrail® system can be planned or an estimate of the cost prepared, the electrical and mechanical requirements that the system must meet should be known. The following outlines list the basic data needed for all applications and the additional data required for various specific applications.

Basic For All

- Describe in detail the purpose for which the Feedrail system will be used. Will it be used with existing equipment?

- How many conductors will be required?

- What voltage and current is to be applied to each conductor? Where is the power source located?

- Details about any special requirements or conditions which the installation must meet such as moisture, corrosive fumes, high or low temperatures, etc.

For Electric Cranes

- Sketch giving number, location, length of crane runways and length of bridge. Show location of building expansion joints or expansion joints in the structure from which the Feedrail® will be supported.

- How many conductors will be required on each bridge run? How many for power? For control? How much current must each conductor carry?

- What is the maximum travel speed of the bridge? of the hoist?

- List of the crane’s motors — main hoist, auxiliary hoist, bridge travel, trolley travel — giving the type (D.C., wound rotor, squirrel cage, etc.) of each motor and its horsepower and full-load ampere rating.

For Electric Hoists

- Plan view sketch of the rail system on which the hoists will travel, giving the length of run, of straight sections, radii of any curves and dimensions of any switches. What is the minimum distance from Feedrail to monorail in order to clear hoist? Show location of building expansion joints or expansion joints in the structure from which the Feedrail® will be supported.

- How many hoists will be used and what is the horsepower and full load current rating of each? Include horsepower and full load current rating of travel motors of any of the hoists that are motor propelled. What are the maximum travel speeds?

For Moving Test Lines

- Plan view sketch with dimensions showing the length of straight sections and radii of any curves, indicate the number of outlets required. If there are any sections along the run where test current will not be required, indicate their location and extent.

- What type of equipment will be tested.

- Give weight of units to be supported by the system.

- What amperage range and what fusing arrangements will be required?

For Production Machines

- Plan view sketch with dimensions showing the location of the Feedrail® system.

- Indicate the number of conductors required and give voltage and amperage requirements of each. Give horsepower and full load current rating of each motor.

- List any other equipment that will be powered by the Feedrail and give its full load current rating.

For Special Requirements

- Plan view sketch with all dimensions which are necessary to make clear the location and extent of the Feedrail system, and the radii of any curves it may contain. Show the location of the power source.

- Full details about equipment which will be operated from the system, including

- Horsepower and full-load current rating of any electrical motors

- Weight of any equipment to be supported by the system.

- Fusing arrangements required.

- Number of outlets needed.

Installation Procedure

Joining Straight to Straight Sections with Coupling Plate (Cat. No. FRS-102)

|

1. Place sections end to end so that ends with and without connectors are facing. Loosen set screws in unattached ends of bus bar connectors to clear openings. Bring track sections together, aligning ends of bars in section being installed with end of the track casing, shifting bus bars slightly if necessary. (Up 1/32” to gap may be left in bus bar joint to permit this alignment.) Bus bar connectors should be center in the casing cutout of the two track sections. Tighten connector set screws. |

|

|

|

|

|

NOTE: Bus Bar Connectors shown above are not provided with track section. Order Catalog No. FRS-102. |

|

Mounting Center Feed Box (Cat. No. FRS-103)

|

1. Replace plain copper bus bar connectors in one track section with terminal connectors of center feed. Place sections end to end so ends with and without connectors are facing. Loosen screws in unattached ends of terminal connectors to clear openings. Slide bus bars into connectors (Up to 1/32” gap may be left in bus bar joint.) Tighten connector set screws. |

2. Hook bottoms of side plates of coupling into underside of track housings and swing up into position so that holes engage studs on sides of housing. Insert clamping screws as shown and screw in tightly. The two track sections are now securely coupled together permitting an uninterrupted path for the trolley travel. Feed set will take standard 2-1/8” deep 4” octagonal extension ring or outlet box or FRS-110 junction box. |

Mounting End Feed Box (Cat. No. FRS-106)

|

1. Slip terminal connectors of end feed on to ends of bus bars and tighten screws. Attach end insulator to terminal connectors. |

2. Mount side plates and end plate-bumper assembly. Mount cover on side plates with two fastening screws. Place the two feed terminal spacers around feed-in terminals and fasten by four holding screws. Feed set will take standard 2-1/8” deep 4” octagonal extension ring or outlet box or FRS-110 junction box. |

Mounting Dead End Cap (Cat. No. FRS-107)

|

1. Mount end insulator by inserting prongs into ends of bus bar connectors as far as they will go and tighten set screws. Hook on dead end cap side plates so that holes engage studs on track housing. Bring plates together as shown. Insert and fasten clamping screws. |

2. Loosen clip on end plate-bumper assembly sufficiently to permit sliding into position as shown. Tighten screws. Place dead end cover in position. Insert the two fastening screws and tighten. |

Installation of Trolleys

|

1. Press pins together on underside of door section and swing door open. |

2. Insert trolley as shown. If trolley hits polarizing strip, remove, reverse 180° and reinsert. Close track doors. |

Preventative Maintenance

At all times Feedrail® equipment should be so protected and maintained as to be kept clean and dry.

Before the Feedrail® system is placed in operation, it should be thoroughly checked for horizontal and vertical alignment, adequate track support and free movement of trolley travel throughout the entire track run. All track, bus bar and feed connections should be mechanically tight. The system should be checked for possible grounds or short circuits. Any paint, grease, or other foreign matter accumulated during construction should be removed from the bus bars, insulation and track interior. Blow out all dust and other loose particles from inside the track.

Expansion sections, when used, must be properly adjusted, located and supported in accordance with installation instructions. Check bus bars and casing for accurate alignment.

Feedrail® is both an electrical and a moving mechanical system and therefore should be included as a part of your Preventive Maintenance Program.

Electrical Maintenance requires:

- Keeping the system dry and clean to prevent electrical leakage or “shorts” across the insulation.

- Maintaining electrical continuity by keeping bus bar contact surfaces clean and joints tight.

Mechanical Maintenance requires:

- Preventing excessive wear.

- Replacing parts showing excessive wear.

The following Preventive Maintenance procedure, periodically performed, is recommended:

- Remove, thoroughly clean all trolleys and lubricate the wheels. Feedrail® recommends Grade #1 Bearing Grease. This is softer grease than #2 and allows the grease to penetrate the bearings easier. Inspect contacts for excessive wear. Replace worn wheels and contacts.

- Clean bus bars with Feedrail® Bus Bar Cleaner.

- Blow out all foreign particles which have accumulated inside the track.

- Check trolleys for free movement within the track.

- Check all track supports, track joints, bus bar and feed connections for tightness. This procedure should be repeated at regular intervals, consistent with the severity of the operations and usage of the system. Plants operating two or three shifts will require more frequent inspection of the Feedrail® equipment.

Feedrail® is not normally recommended for installations subject to vibration, frequent electrical overload, corrosive fumes and other abnormal conditions. However, should such conditions exist, more frequent inspections and maintenance will be required.

Before additional electrical loads are added to the system, it should be determined that sufficient capacity is available.

Basic Dimensions/Mounting Methods

Basic Dimensions

As an aid in planning mountings, the basic dimensions of the Feedrail® 60 system is shown below. These are offered as a guide only.

Mounting Methods

Examples of the methods commonly used for mounting the Feedrail® '60' system is shown below. These methods can be used in existing plants as well as in new buildings. Engineers and contractors will readily be able to devise other methods to suit special installations. In every case the mounting should be designed to insure a rigid installation in both horizontal and vertical alignment.

(Click image for full-size view)

Typical Specification

As an aid to preparing specifications for a Feedrail® installation, the following wording is suggested. You will note this specification contains the primary electrical and mechanical features of the Genuine Feedrail® System.

FRS100 & FRS200 Series (Feedrail® '60')

The Trolley and Plug-in Busway System (Crane and Hoist Electrification System) shall be of the metal enclosed type with internally track-supported trolleys and plug-in jacks as manufactured by:

Genuine Feedrail®

Industrial Products

The System shall have a voltage rating 300 Volts A.C. or D.C. (2 Pole) (3 Pole) and a continuous current carrying capacity of 60 Amperes per Pole. (When used as a Crane and Hoist Electrification System, the System shall be rated at 60 Amperes continuous service and 90 Amperes intermittent service). The full current carrying capacity of the system shall be maintained throughout. The system shall permit longitudinal movement of the housings and bus bars, independent of each other, in order to allow for unequal expansion and contraction as a result of temperature changes. The System shall consist of standardized, interchangeable, Feedrail® units — track sections, coupling sets, dead end caps, track hangers and power takeoff trolleys and jacks, as called for on the plans.

Track sections shall be one piece, 18 gauge, rolled, zinc-coated sheet steel enclosures having a continuous slot in the bottom and a heavy keystone shaped rib in the top. Rolled or drawn copper bus bars, capable of carrying 60 Amperes per pole continuously without overheating, shall be mounted within the steel enclosure on arc-resistant insulators.

Door track sections shall include two hinged doors in the bottom for insertion and removal of trolleys. Door openings shall have a mechanical polarization to insure proper polarity of the trolleys.

Track supported trolleys shall be Cat. No._______________________ as listed in the Feedrail® Catalog. They shall have a zinc-plated sheet steel chassis with metal wheels for support. Horizontal guide wheels shall run in the slot of the Feedrail® track to prevent slewing and maintain alignment.

Springloaded roller (or brush) contacts shall be mounted on arc-resistant insulation. When inserted in the Feedrail® track, the contacts shall align with the bus bars at all times.

Trolleys shall be mechanically polarized withcontact with the bus bars.

Plug-In Jacks can be inserted in the track slot at any point. A quarter turn, after insertion, makes electrical contact and locks the Jack in place.

Build Your Feedrail FRS100 or FRS200 Series System

All of the components you’ll need to build a brand new Feedrail FRS100 or FRS200 Series system have been organized below by category. It is recommended that you start with Track Sections and work your way through each category in the order they’re presented. If you have any questions, please contact us and one of our highly trained Feedrail specialists will respond shortly.

Track Sections |

Track Accessories & Hangers |

Plug-In Jacks |

Trolleys |

Track & Busway Cleaning Tools |

Replacement Parts |

Browse & Shop for FRS100 or FRS200 Series System Components & Parts

All components and parts for the Feedrail FRS100 and FRS200 can be found below. Use the product filter menu to narrow your search.

Electro-Rail 10’ Straight Track – 2 Pole, 60 Amp

Item Number: 12216

10 foot straight track section. 2 pole, 60 amp, 300 volt AC/DC busway. Fits Feedrail FRS100 & FRS200.

Electro-Rail 5’ Straight Track – 2 Pole, 60 Amp

Item Number: 12217

5 foot straight track section. 2 pole, 60 amp, 300 volt AC/DC busway. Fits Feedrail FRS100 & FRS200.

Electro-Rail 10’ Straight Track – 3 Pole, 60 Amp

Item Number: 12277

10 foot straight track section. 3 pole, 60 amp, 300 volt AC/DC busway. Fits Feedrail FRS100 & FRS200.

Electro-Rail 5’ Straight Track – 3 Pole, 60 Amp

Item Number: 12278

5 foot straight track section. 3 pole, 60 amp, 300 volt AC/DC busway. Fits Feedrail FRS100 & FRS200.

Electro-Rail 10’ Straight Track with Door – 2 Pole, 60 Amp

Item Number: 12219

10 foot straight track with trolley door. 2 pole, 60 amp, 300 volt AC/DC busway. Fits Feedrail FRS100 & FRS200.

Electro-Rail 5’ Straight Track with Door – 2 Pole, 60 Amp

Item Number: 12220

5 foot straight track with trolley door. 2 pole, 60 amp, 300 volt AC/DC busway. Fits Feedrail FRS100 & FRS200.

Electro-Rail 10’ Straight Track with Door – 3 Pole, 60 Amp

Item Number: 12279

10 foot straight track with trolley door. 3 pole, 60 amp, 300 volt AC/DC busway. Fits Feedrail FRS100 & FRS200.

Electro-Rail 5’ Straight Track with Door – 3 Pole, 60 Amp

Item Number: 12280

5 foot straight track with trolley door. 3 pole, 60 amp, 300 volt AC/DC busway. Fits Feedrail FRS100 & FRS200.

Electro-Rail Coupling Set for FRS100 & FRS200 Series

Item Number: 12281

Coupling set for FRS100 & FRS200 Series. Side plates with cover for coupling adjacent straight track sections. Provided with Bus Bar Connectors. One coupling is required for every two sections of track joined.

Electro-Rail Dead End Cap for FRS100 & FRS200 Series

Item Number: 12286

Dead end cap for FRS100 & FRS200 Series. For closing the end of a straight track run. Similar to coupling FRS-102 with the addition of removable end insulator, end plate and bumper.

Electro-Rail Center Feed Set – 3 Pole, 60 Amp

Item Number: 12282

Center feed set for FRS100 & FRS200 Series. For electrical connection to the power supply between adjoining straight track sections. Also serves as a track coupling.

Electro-Rail End Feed Set – 3 Pole, 60 Amp

Item Number: 12285

End feed set for FRS100 & FRS200 Series. For electrical connection to the power supply and closing the end of a straight track run.

Electro-Rail Low Level End Feed – 3 Pole, 60 Amp

Item Number: 12225

Low-level end feed for FRS100 & FRS200 Series. For electrical connection to the power supply and closing the end of a straight track run where insufficient head room exists for use of the FRS-106 end feed. Junction box has 1" and 1-1/4" knockouts on three sides.

Electro-Rail Junction Box for FRS100 and FRS200 Series

Item Number: 12288

Used with center or end feed set for electrical connection to the power supply. Box has 1" and 1-1/2" knockouts on three sides.

Electro-Rail Tie Rod Hanger

Item Number: 12291

Track hanger for tie rod. Fits FRS100 & FRS200 Series, also FRS300 Plug-In Series. Allows direct attachment of 3/8" tie rods at any point between track joints. Permits easy leveling of track sections. When used with curved track, field notching of track top flange is required for clearance of clamping bolt. A minimum of two track hangers required for each straight track section.

Electro-Rail Straight Track Hanger

Item Number: 12284

Track hanger for FRS100 & FRS200 Series, also FRS300 Plug-In Series. For mounting straight track sections. Mounting hole will take 3/8" diameter bolt. They can be attached to straight track at any point between track joints. Not suitable for curved track sections. Minimum of two track hangers required for each straight track section.

Electro-Rail Clevis Support for Tie Rod Installations

Item Number: 12283

Clevis support for tie rod applications. Malleable iron, with 3/8" cross bolt and 3/8"-16 tapped hole for tie rod. Must be used in conjunction with FRS-124 and FRS-105 track hangers.

Electro-Rail Duplex Busway Hanger Set

Item Number: 11675

Duplex busway hanger set. For FRS100 & FRS200 Series, also FRS300 Plug-In Series. For 10' support spacing to be used at track joint over coupling.

Electro-Rail Low-Level Track Hanger

Item Number: 12363

Hanger (low level). For FRS100 & FRS200 Series, also FRS300 Plug-In Series. Used in place of track hanger FRS-105 where head room is limited. Takes 3/8" diameter bolts. Can be attached to straight track at any point between track joints. Not suitable for curved track. Minimum of two track hangers required for each straight track section.

Electro-Rail Non-Fusible Standard Plug In Jack with 6" leads – 3 Pole, 15 Amp

Item Number: 12766

Non-fusible. Inside Bracket Length 2.12” (53.87mm). Standard 6” leads. 3 Poles, 15 amps, 300 volts AC.

Electro-Rail Non-Fusible Plug-In Jack with Junction Box – 3 Pole, 15 Amp

Item Number: 12767

Non-fusible with junction box and cable clamp. 3 Poles, 15 amps, 300 volts AC.

Electro-Rail Non-Fusible with Box and NEMA Type 5-15R Receptacle – 2 Pole, 15 Amp

Item Number: 12760

Non-fusible with junction box and NEMA type 5-15R receptacle. 2 poles, 15 amps, 125 volts DC.

Electro-Rail Fusible Plug-In Jack with Cabinet and Fuse Block – 3 Pole, 15 Amp

Item Number: 17742

Fusible with cabinet and fuse block. 3 poles, 15 amps, 250 volts AC. Steel hinged door cabinet. Takes 9/16" x 2" long cartridge fuses. Includes cartridge fuse block and cable support lug.

Electro-Rail Replacement Only Plug-In Jack Assembly – 3 Pole

Item Number: 17742S

Plug-in-jack assembly. Replacement only. 3 pole, 15 amps, 250 volts AC.

Electro-Rail Fusible Plug-In Jack with Cabinet, Fuse Block and NEMA Type 5-15R Receptacle – 2 Pole, 15 Amp

Item Number: 12241

Fusible with cabinet, fuse block and NEMA type 5-15R receptacle. 2 poles, 15 amps, 125 volts AC.

Electro-Rail Moveable Roller Trolley – 2 Pole, 5 Amp

Item Number: 12259

Standard type moveable roller trolley. Non-fusible with cable clamp. For FRS100 & FRS200 Series. 2 poles, 5 amps, 300 volts AC/DC. Copper graphite roller contact.

Electro-Rail Moveable Roller Trolley – 3 Pole, 5 Amp

Item Number: 12246

Standard type moveable roller trolley. Non-fusible with cable clamp. For FRS100 & FRS200 Series. 3 poles, 5 amps, 300 volts AC/DC. Copper graphite roller contact.

Electro-Rail Moveable Trolley – 2 Pole, 15 Amp

Item Number: 12212

Standard type moveable trolley. Non-fusible with cable clamp. For FRS100 & FRS200 Series. 2 poles, 15 amps, 300 volts AC/DC. Copper graphite brush contact.

Electro-Rail Moveable Trolley – 3 Pole, 15 Amp

Item Number: 12233

Standard type moveable trolley. Non-fusible with cable clamp. For FRS100 & FRS200 Series. 2 poles, 15 amps, 300 volts AC/DC. Copper graphite brush contact.

Electro-Rail Standard Non-Fusible Trolley with Cable Clamp and Tool Hanger – 3 Pole, 5 Amp

Item Number: 12230

Standard type trolley. Non-fusible with cable clamp and tool hanger. 3 poles, 5 amps, 300 volts AC/DC. Copper graphite brush roller. Note: Not to exceed 20 pounds per trolley.

Electro-Rail Standard Non-Fusible Trolley with Cable Clamp and Tool Hanger – 3 Pole, 15 Amp

Item Number: 12237

Standard type trolley. Non-fusible with cable clamp and tool hanger. 3 poles, 15 amps, 300 volts AC/DC. Copper graphite brush. Note: Not to exceed 20 pounds per trolley.

Electro-Rail Special Service Non-Fusible with Box and Cable Clamp – 3 Pole, 20 Amp

Item Number: 12273

Standard type trolley. Non-fusible with box and cable clamp. 3 poles, 20 amps, 300 volts AC/DC. Copper graphite brush.

Electro-Rail Standard Non-Fusible with Box and Cable Clamp – 3 Pole, 30 Amp

Item Number: 12232

Standard type trolley. Non-fusible with box and cable clamp. 3 poles, 30 amps, 300 volts AC/DC. Copper graphite brush.

Electro-Rail Fusible Roller Trolley with Cabinet, Fuse Block and Cable Clamp – 3 Pole, 5 Amp

Item Number: 12248

Fusible roller trolley with cabinet, fuse block and cable clamp. 3 poles, 5 amps, 250 volts AC/DC. Copper graphite roller contact. Note: Fuses are not included. Fusible Trolleys take 9/16" x 2"cartridge fuses.

Electro-Rail Standard Fusible Trolley with Cabinet, Fuse Block and Cable Clamp – 3 Pole, 15 Amp

Item Number: 12228

Fusible roller trolley with cabinet, fuse block and cable clamp. 3 poles, 15 amps, 250 volts AC/DC. Copper graphite brush contact. Note: Fuses are not included. Fusible Trolleys take 9/16" x 2"cartridge fuses.

Electro-Rail Fusible Special Service Trolley with Cabinet, Fuse Block and Cable Clamp – 3 Pole, 20 Amp

Item Number: 12274

Fusible roller trolley with cabinet, fuse block and cable clamp. 3 poles, 20 amps, 250 volts AC/DC. Copper graphite brush contact. Note: Fuses are not included. Fusible Trolleys take 9/16" x 2"cartridge fuses.

Electro-Rail Standard Fusible Trolley with Cabinet, Fuse Block and Cable Clamp – 3 Pole, 30 Amp

Item Number: 12239

Standard type trolley with cabinet, fuse block and cable clamp. 3 poles, 30 amps, 250 volts AC/DC. Copper graphite brush contact. Note: Fuses are not included. Fusible Trolleys take 9/16" x 2"cartridge fuses.

Electro-Rail Non-Fusible Transfer Trolley with Box and Cable Clamp – 3 Pole, 20 Amp

Item Number: 12243

Transfer type trolley, non-fusible with box and cable clamp. 3 poles, 20 amps, 300 volts AC/DC. Copper graphite brush contact.

Electro-Rail Non-Fusible Transfer Trolley with Box and Cable Clamp – 3 Pole, 30 Amp

Item Number: 12245

Transfer type trolley, non-fusible with box and cable clamp. 3 poles, 30 amps, 300 volts AC/DC. Copper graphite brush contact.

Electro-Rail Dust Remover with Bristle Brushes

Item Number: 12226

Dust remover with bristle brushes for FRS100 & FRS200 series track.

Electro-Rail Busway Cleaning Tool

Item Number: 12272

Busway cleaning tool for FRS100 & FRS200 series track.

Electro-Rail 10' Finished Bus Bar

Item Number: T11382P

10' finished bus bar for FRS 100 & 200 Series.

Electro-Rail Bus Bar Insulator for FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12307

Bus bar connector and insulator for FRS 100 & 200 Series). For straight track only.

Electro-Rail Bus Bar Connector for FRS100 & FRS200 Plug-In & Trolley Series and FM & FX Multi-Conductor Trolley Series

Item Number: 12320

Bus bar connector for FRS 100 & 200 Series, also FM & FX Series (Multi-Conductor Trolley Service 2, 3 and 4 pole).

Electro-Rail Coupling Insulator for FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 61327

Coupling insulator for FRS 100 & 200 Series.

Electro-Rail Terminal Feed Assembly for FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12315

1 pole terminal feed for FRS 100 & 200 Series.

Electro-Rail Terminal Spacer for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12309

Terminal spacer for FRS 100 & 200 Series (Feedrail® '60'). Note: 2 required per feed box.

Electro-Rail Bus Bar Terminal Spacer for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12308

Bus bar spacer for FRS 100 & 200 Series (Feedrail® '60').

Electro-Rail Track Door Hinge for FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12317

Track door hinge for FRS 100 & 200 Series (Feedrail® '60'). Note: 2 required per door section.

Electro-Rail 117" Polarizing Strip for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 13865

117" ERS300M polarizing strip for FRS 100 & 200 Series (Feedrail® '60'). Used with plug-in jacks for porper insertion into track.

Electro-Rail 5' Safety Strip for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 13866

Five foot safety strip for FRS 100 & 200 Series (Feedrail® '60'). Used to cover track openings for maximum operator safety.

Electro-Rail Dust Remover Bristle Brush for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12321

Dust remover bristle brush used for cleaning dust from FRS100 and FRS200 series.

Electro-Rail Track Cleaner Stone Assembly

Item Number: 12325

Cleaner stone assembly for FRS 100 & 200 Series (Feedrail® '60'), FM Series (Multi-Conductor Trolley Service 2,3 and 4 pole) and FX Series (Multi-Conductor Trolley Service 4 and 5 Pole).

Electro-Rail 2 Pole Trolley Body Assembly with Copper Graphite Roller Contacts – 2 Pole, 5 Amp

Item Number: 12340

2 pole trolley body assembly with copper graphite roller contacts for FRS 100 & 200 Series (Feedrail® '60'). 5 amps.

Electro-Rail 3 Pole Trolley Body Assembly with Copper Graphite Roller Contacts – 3 Pole, 5 Amp

Item Number: 12327

3 pole trolley body assembly with copper graphite roller contacts for FRS 100 & 200 Series (Feedrail® '60'). 5 amps.

Electro-Rail 5 Amp Copper Graphite Roller Contact

Item Number: 12299

5 amp copper graphite roller contact assembly.

Electro-Rail 2 Pole Trolley Body Assembly with Copper Graphite Roller Contacts – 2 Pole, 15 Amp

Item Number: 12338

2 pole trolley body assembly with copper graphite brush contacts for FRS 100 & 200 Series (Feedrail® '60'). 15 amps.

Electro-Rail 3 Pole Trolley Body Assembly with Copper Graphite Roller Contacts – 3 Pole, 15 Amp

Item Number: 12333

3 Pole trolley body assembly with copper graphite brush contacts for FRS 100 & 200 Series (Feedrail® '60'). 15 amps.

Electro-Rail 15 Amp Copper Graphite Brush Contact

Item Number: 12303

Copper graphite brush contact assembly for FRS 100 & 200 Series (Feedrail® '60'). 15 amps.

Electro-Rail Trolley Body for Feedrail FRS100 & FRS200 Plug-In & Trolley Series – 5 & 15 Amp

Item Number: 12296

Trolley body for FRS 100 & 200 Series (Feedrail® '60'). 5 and 15 amps.

Electro-Rail Trolley Chassis for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12304

Trolley chassis for FRS 100 & 200 Series (Feedrail® '60'). 5 and 15 amps.

Electro-Rail Trolley Chassis Liner for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12310

Chassis liner for FRS 100 & 200 Series (Feedrail® '60'). 5 and 15 amps.

Electro-Rail Contact Retaining Plate for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12311

Contact retaining plate for FRS 100 & 200 Series (Feedrail® '60'). 5 and 15 amps.

Electro-Rail Contact Retaining Plate Screw for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12305

Contact retaining plate screw for FRS 100 & 200 Series (Feedrail® '60').

Electro-Rail Outside Contact Assembly with Copper Graphite Brush – 20 Amp

Item Number: 12301

Outside copper graphite brush contact assembly for FRS 100 & 200 Series (Feedrail® '60'), also for ERS-84 and ERS-86. 20 amps.

Electro-Rail Center Contact Assembly with Copper Graphite Brush – 20 Amp

Item Number: 12302

Center copper graphite brush contact assembly for FRS 100 & 200 Series (Feedrail® '60'), also for ERS-84 and ERS-86. 20 amps.

Electro-Rail Outside Contact Assembly with Copper Graphite Brush – 30 Amp

Item Number: 12334

Outside copper graphite brush conact assembly for FRS 100 & 200 Series (Feedrail® '60'). 30 amps.

Electro-Rail Center Contact Assembly with Copper Graphite Brush – 30 Amp

Item Number: 12336

Center copper graphite brush conact assembly for FRS 100 & 200 Series (Feedrail® '60'). 30 amps.

Electro-Rail Trolley Body for Feedrail FRS100 & FRS200 Plug-In & Trolley Series – 20 & 30 Amp

Item Number: 12297

Trolley body for FRS 100 & 200 Series (Feedrail® '60'), also for ERS-84 & ERS-86. 20 and 30 Amps.

Electro-Rail Standard Trolley Chassis for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12312

Chassis assembly for standard trolleys. Fits FRS 100 & 200 Series (Feedrail® '60'), also ERS-84 and ERS-86. 20 and 30 amps.

Electro-Rail Transfer Type Trolley Chassis for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12367

Chassis assembly for transfer type trolleys. Fits FRS 100 & 200 Series (Feedrail® '60'). 20 and 30 amps.

Electro-Rail 2 Piece Thermal Insulator for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 17167

2 piece terminal insulator.

Electro-Rail Terminal Connector for FRS100, FRS200, ERS-84, ERS-86 & E60

Item Number: 12316

Terminal connector for FRS 100 & 200 Series (Feedrail® '60'), also ERS-84 and ERS-86.

Electro-Rail 10’ Straight Track Casing for FRS100, FRS200 & FRS300 Series

Item Number: 12277C

Electro-Rail 10 foot straight track casing for FRS100, FRS200 & FRS300 Series.

Electro-Rail Straight Track End Cap for FRS100, FRS200 & FRS300 Series

Item Number: 11669EC

Electro-Rail straight track end cap for FRS100, FRS200 & FRS300 Series.

Electro-Rail Trolley Body Mounting Screw for Feedrail FRS100 & FRS200 Plug-In & Trolley Series

Item Number: 12306

Trolley body screw for FRS 100 & 200 Series (Feedrail® '60') and for ERS-84 and ERS-86.